Solvent Recovery System for Solvent Recycling

Introduction

In today’s industrial landscape, the efficient use and disposal of solvents is crucial for both economic and environmental reasons. A solvent recovery system offers a practical solution to this challenge, providing significant benefits in terms of cost savings and sustainability. Here, we explore why using a solvent recovery system is essential and how it works.

Why Use a Solvent Recovery System?

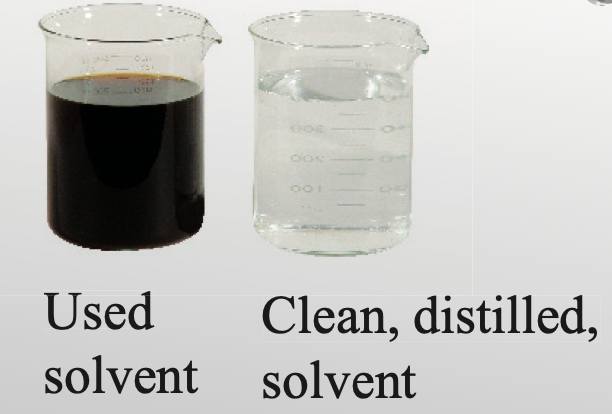

Solvent recovery systems, also known as solvent recyclers, are designed to remove soils, debris, and oils from used cleaning solvents through a process called distillation. This allows the cleaned solvent to be reused multiple times, reducing the need for new solvent purchases by over 90% and cutting down chemical waste disposal costs by a similar margin. Here’s why investing in a solvent recovery system is a smart move:

- Cost Savings: Chemical disposal can be unexpectedly expensive. By using a solvent recycler, businesses can drastically reduce both disposal costs and the costs associated with purchasing new solvents.

- Environmental Impact: Reducing chemical waste is not only cost-effective but also environmentally responsible. A solvent recovery system minimizes the environmental footprint of industrial processes.

These systems can recycle and recover a wide range of solvents used in various industries, including:

- Paint body shops

- Automotive factories

- Collision repair shops

- Oil & gas industries

- Energy industries

- Metalworking industries

- Chemical industries

Moreover, Uni-ram’s URS500 & 600 series solvent recyclers are specifically designed to ensure safety when handling flammable solvents.

Solvent Requirements in Solvent Recovery System

When considering a solvent recovery system, it’s important to understand the requirements for the solvents being recycled:

- Flammable Solvents: This includes lacquer thinner, paint thinner, acetone, and other paint diluents, which have a flash point below 38.7°C (100°F). These solvents are widely used as cleaning agents or paint diluents.

- Boiling Point (BP): The dirty solvent’s boiling point must be less than 200°C (392°F). It’s crucial to recycle recently contaminated solvent as standing solvent can become acidic over time.

- Auto-Ignition Temperature: For safe operation, the solvent’s auto-ignition temperature must be higher than 260°C (500°F). Note: Nitrocellulose should not be recycled due to its low auto-ignition temperature of 135°C (275°F).

How Does a Solvent Recovery System Work?

Solvent recovery systems utilize the process of distillation to separate and purify solvents. Distillation leverages the different boiling points of the mixture’s components, involving two main steps: vaporization and condensation.

Vaporization: The mixture is heated to the boiling point of the component with the lowest boiling point. This causes that component to vaporize while the others remain in liquid form. For example, in a mixture of water and ethanol, heating the mixture to around 78.37°C will vaporize the ethanol.

Condensation: The vaporized component is then directed into a cooling area where it condenses back into a liquid. By lowering the temperature, the vapor molecules lose kinetic energy and transition back to the liquid phase, separating them from the other components.

This fundamental technique is widely used in chemistry and industrial processes to achieve high levels of solvent purity.

Spotlight on the URS500 & 600 Series Solvent Recyclers: A Sustainable Solution

The URS500 & 600 Series solvent recyclers are the favorites of paint and body shops for good reason. The URS500 Solvent Recycler, in particular, provides clean, recycled solvent every day, handling typical solvents such as paint thinner, gun wash solvent, and acetone with ease. This daily recycling capability significantly reduces a shop’s environmental footprint and operational costs.

With the URS500 & 600 Series solvent recyclers, shops can generate 5 gallons of clean recycled solvent from each recycling batch, leading to a dramatic decrease in solvent purchases and offsite waste transport costs—approximately 90%. These solvent recyclers are at the core of Uni-ram’s environmentally friendly solutions, which include innovative spray gun cleaners and parts washers that maximize solvent reuse.

By utilizing the URS500 & 600 Series, automotive solvent recyclers can effectively reduce hazardous solvent waste, enhancing both the environmental sustainability and cost-efficiency of their operations. This dual benefit makes the URS500 & 600 Series indispensable for businesses looking to improve their eco-friendliness while maintaining high operational standards.

Conclusion

A solvent recovery system is a valuable investment for industries relying heavily on solvents. By significantly reducing both the cost of new solvent purchases and the disposal of chemical waste, these systems offer a compelling return on investment. Additionally, they contribute to a more sustainable and environmentally friendly operation. With advanced systems like Uni-ram’s URS 500 & 600 series, businesses can safely and efficiently recycle even flammable solvents, ensuring both economic and environmental benefits.

Explore our range of Solvent Recyclers today and find the perfect match for your needs. For more detailed information and assistance in selecting the right Spray Gun Cleaner Machine or system, please contact us. Elevate your solvent management strategy with our state-of-the-art Spray Gun Cleaning Solutions and take a step towards a more sustainable and efficient future.

Equip your business with Uni-ram’s advanced cleaning solutions and experience a new standard in maintenance efficiency and environmental stewardship.

For more details on implementing these strategies in your solvent recycling practices, please feel free to contact us. We are here to provide additional information and guidance tailored to your specific needs and requirements.

In light of the imperative nature of addressing climate change, the reduction of industrial carbon emissions has transitioned from being a mere choice to an absolute necessity. Uniram Corp. provides eco-friendly Solvent Recycling Systems, along with additional strategies, offering a comprehensive approach to attaining sustainability goals. Through the embrace of innovation, collaborative efforts, and a steadfast commitment to sustainability, industries can lead the way towards a greener and more sustainable future, concurrently enhancing their financial bottom lines.

Industries play a pivotal role in the collective pursuit of carbon neutrality and a healthier planet. By incorporating these strategies, you have the potential to substantially diminish your industrial carbon emissions footprint, actively contributing to the creation of a more sustainable industrial landscape. For further insights into these approaches and tailored solutions, please don’t hesitate to reach out to us. We are here to provide additional information and assistance to meet your specific needs and aspirations.