- Home

- All products

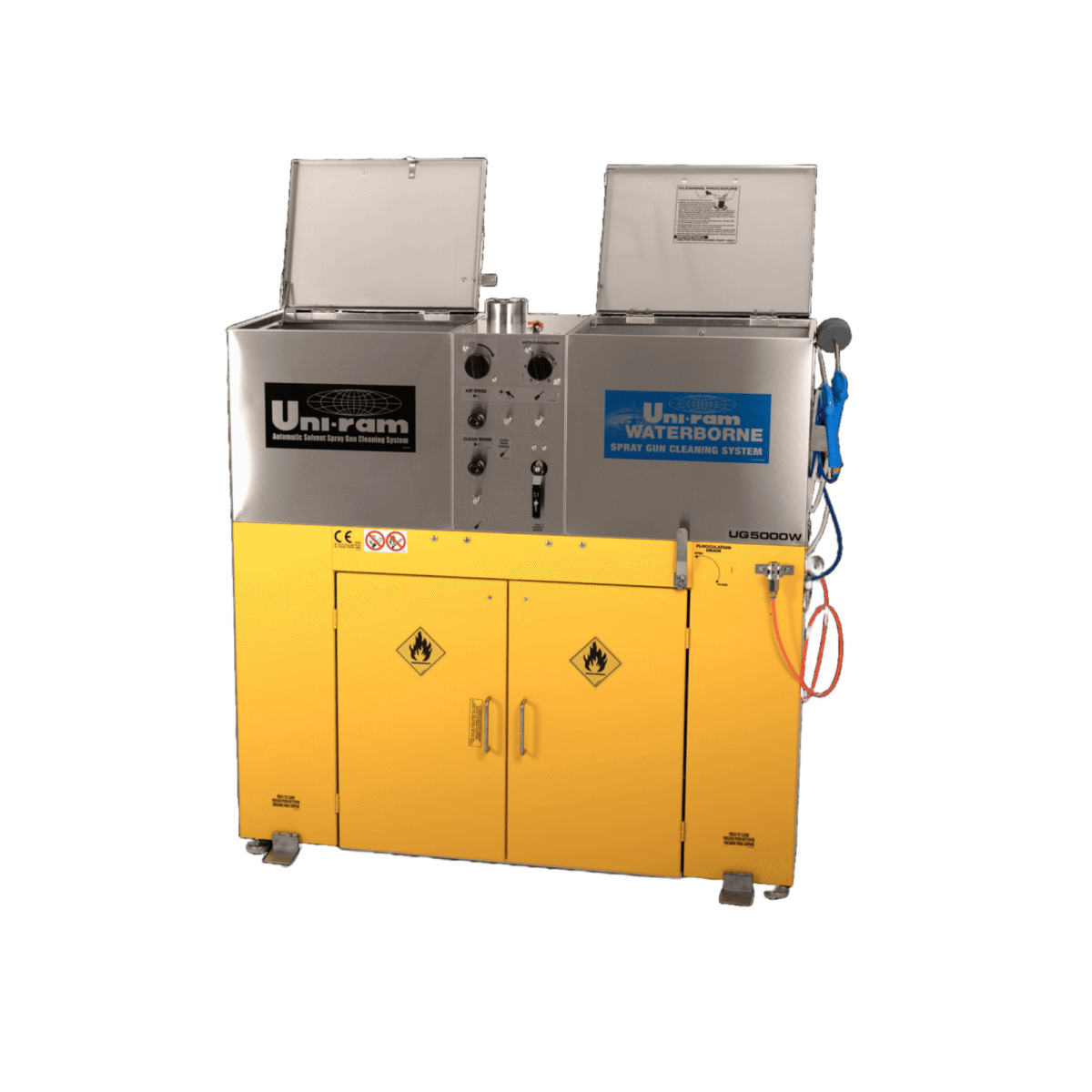

- UG5000W Spray Gun Washers

SKU:

UG5000W Spray Gun Washers

$5,885.00 – $6,600.00

UG5000W is our most popular spray gun washer. Spray guns for primers and clear coat paints are cleaned in the solvent tank and spray guns for waterborne base coat are cleaned in the water tank. The UG5000W meets all the spray gun cleaning needs of the shop in one cabinet. One work station is more efficient than 2 separate work stations. The shop saves space and the uses one less airline.

Specifications

Product Description

Applications

Additional Information

Specifications

- Model: UG5000W

- Gun Cleaned: 2 Spray Guns & 2 Pots

- Air flush: Yes

- Rinse: Brush, Wash Gun

- Diaphragm Pumps: 3

- Shipping Dimension (WDH): 47 x 17 x 46

- Weight (lb/kg): 170 / 77

- Operation: Automatic

- Capacity: Waterborne / Solvent

- Requires minimum of 85 PSI, 2 CFM of clean dry air. Pressure regulator is built in.

Product Description

UG5000W is our most popular spray gun washer. Spray guns for primers and clear coat paints are cleaned in the solvent tank and spray guns for waterborne base coat are cleaned in the water tank. The UG5000W meets all the spray gun cleaning needs of the shop in one cabinet. One work station is more efficient than 2 separate work stations. The shop saves space and the uses one less airline.、

Specifications:

- Top loading. Cleans 2 spray guns in under 1 minute.

- Wash Tank is constructed from stainless steel for longer life. The tank size is 17.25″ w x 13.5″ d x 14″h. (44cm w x 34cm d x35cm h).

- Washing is activated by a wash timer and powered by a long-lasting dual diaphragm pump that outputs 3.7 gallons of solvent per minute.

- The flow of solvent through the brush is activated by a foot pedal and powered by a 2″ dual diaphragm pump. Flow is adjustable.

- Mounting adapters fit popular conventional cup systems and disposable cup systems to deliver solvent to thoroughly wash the paint channel.

- 14 swirl action jets deliver solvent to wash the over spray from the spray guns.

- The pump halts immediately if the lid is raised during cleaning, to prevent exposure to solvent, providing a safe operation.

- Stainless steel mesh filter keeps solvent cleaner and keeps debris from reaching the diaphragm pump.

- Plastic Cone prevents solvent from entering air passageway. Cone also provides positive air flow through the air passageway to keep solvent from entering at the cap.

- Fume extractor automatically removes solvent fumes from the work area when the lid is raised for a healthier work environment.

- Lower cabinet is powder-coated paint on mild steel with a closing door, floor and adjustable feet.

- Closing the drain valve located under the cleaning tank prevents solvent spillage when refilling the wash pail.

- Comes with 2 solvent pails inside the cabinet, trigger clamps and SOPs.

- CE Approved.

Solvent Tank (Left Side)

The automatic cleaning cycle in the solvent tank consists of automatic wash using the 4″ diaphragm pump, air rinse and clean rinse. The Flow-through brush is used to remove hardened over spray from the spray gun.

Operation:

- Place the spray gun on the mounting adapter in the cleaning tank and turn the automatic timer. A 4 inch diaphragm pump drives solvent up through 1) the mounting adapters to flush the paint channel of the spray gun and 2) through 14 spray jets to wash over spray from the outside of the gun. Solvent drains back into the wash pail, for reuse, a green approach.

- Press the air rinse button to flush the wash solvent and then press the clean rinse button to send 100 CC of clean solvent through the jets to rinse the spray guns. Two guns are cleaned in 1 minutes.

Waterborne Tank (Right Side)

UG5000w Spray Gun Cleaners Manual cleaning consists of flushing the paint channel with the water gun, washing the overspray from the gun with the brush and drying the gun with the blow gun.

Operation:

- The painter flushes the spray gun using the water gun into a supplied, stainless steel EPA 6H compliant spray capture tube in under 10 seconds. Most painters can get around 30 spray gun cleanings from the 5 gallons of clean, AQUA KLEEN enriched water. The flow-through brush removes overspray and the blow gun dries the spray gun. Dirty water drains into a reservoir and is later treated with COAGKLEEN FP then filtered. The clean filtered water is reused for cleaning spray guns.

- Requires minimum of 85 PSI, 2 CFM of clean dry air. Pressure regulator is built in.

- Pump for automatic solvent wash: 4″ dual diaphragm pump with unique shuttle valve for long life, output is 3.7 gal/min (14 L/min).

- Pump for water gun and brush is a 2″ dual diaphragm pump with unique shuttle valve for long life, output is 1.9 gal/min (7 L/min).

- Cleans solventborne and waterborne paints from spray guns.

- Shipping Dimensions: 47″w x 17″d x 47″h (119cmW x 43cmD x 119cmH) Shipping Weight: 190 lb.

- Product Dimensions: 43.2″w x 13.6″d x 43.0″h (110cmW x 34.5cmD x 110.0cmH)

Benefit:

Lower disposal costs since the water can be reused several times before disposal. Shop Operations becomes “Greener”.

To use, add 2 scoops of COAG-KLEEN FP powder per 5 gal (20L) of spent water. Agitate for 5 minutes then drain through the Uni-ram COAG-KLEEN FP filter system. It removes the absorbed waste paint solids from the water used to clean spray guns.

- Primary Filter Pad: 102-8125

- Secondary Filter Pad: 102-8126

Applications

Applications:

The Uni-Ram UG5000W Spray Gun Washer is ideal for recycling solvents used in a variety of industries, including:

- Manufacturing

- Coating

- Automotive

- Metal Finishing

- Printing & Ink

- Electrical

- Oil & Gas

- Fiberglass

- Furniture & Cabinetrv

- Aerospace &Marine

- and more

Additional Information

- Requires minimum of 85 PSI, 2 CFM of clean dry air. Pressure regulator is built in.

- Pump for automatic solvent wash: 4″ dual diaphragm pump with unique shuttle valve for long life, output is 3.7 gal/min (14 L/min).

- Pump for water gun and brush is a 2″ dual diaphragm pump with unique shuttle valve for long life, output is 1.9 gal/min (7 L/min).

- Cleans solventborne and waterborne paints from spray guns.

- Shipping Dimensions: 47″w x 17″d x 47″h (119cmW x 43cmD x 119cmH)

- Shipping Weight: 190 lb.

- Product Dimensions: 43.2″w x 13.6″d x 43.0″h (110cmW x 34.5cmD x 110.0cmH)