How to Recycle Solvents Easily - The Best Solvent Recovery Solution

Introduction

Recycling solvents is a critical practice for industries that rely heavily on chemical processes, such as pharmaceuticals, painting, and printing. It not only reduces hazardous waste but also cuts down on the costs associated with purchasing new solvents. This blog explores two efficient ways to handle solvent waste: off-site solvent waste handling and on-site solvent recycling.

Off-Site Solvent Recycling

Off-site solvent waste handling involves sending waste solvents to a specialized facility where they are treated, recycled, and sometimes returned to the industry as clean, reusable solvents. This process is ideal for companies that may not have the capacity or resources to handle solvent recovery internally.

With labor shortages, many facilities believe that outsourcing hazardous solvent waste processing allows them to allocate all available manpower to production. However, this reasoning is flawed. Facilities that utilize solvents and subsequently ship them out as waste are burdened with considerable transportation, receiving, and material movement onsite. Consider the sequence: procurement teams spend significant time finding the best prices for new solvents and managing orders. Upon arrival—often in drums—staff must handle reception and storage. The solvent must then be manually transported for use in production or cleaning. After use, it is collected in waste drums, which must be moved to a 90-day hazardous waste storage area. Environmental Health & Safety (EH&S) personnel are tasked with waste reporting and coordinating pickups with waste companies. When the truck arrives, employees must move all these drums to the loading bay, restarting the cycle with new solvent orders.

Although off-site solvent recycling is a greener practice, it similarly consumes substantial labor due to the continuous shipment and handling of drums. Instead of receiving new solvent shipments, facilities receive recycled solvent. While this is undoubtedly better for the environment, it does not mitigate the pervasive labor shortages.

Reflecting on the off-site solvent waste management process reveals the immense amount of labor involved in preparing, receiving, moving, and shipping drums of solvent across the job site. More inventory leads to increased handling, liability, and carbon footprint. These methods are not optimal for addressing labor shortages but merely serve as temporary fixes for facilities that have not yet optimized their waste management strategies to effectively confront global labor shortages. The real solution lies in on-site solvent recycling!

Benefits of Off-Site Handling

- Expert Management: Off-site facilities are equipped with sophisticated technology specifically designed for solvent recovery. This means they can often achieve higher rates of solvent purity and recovery.

- Compliance and Safety: These facilities are well-versed in regulatory requirements and ensure that your company complies with environmental laws, reducing the risk of legal complications.

- Reduced Investment: By outsourcing solvent recovery, companies can avoid the high initial investment and ongoing operating costs associated with on-site recycling systems.

Choosing the Right Service Provider

Selecting an off-site recycling provider requires careful consideration of their processing capabilities, compliance with environmental regulations, and the logistics of transporting hazardous waste. Ensure they offer transparent processes and can tailor their services to your specific needs.

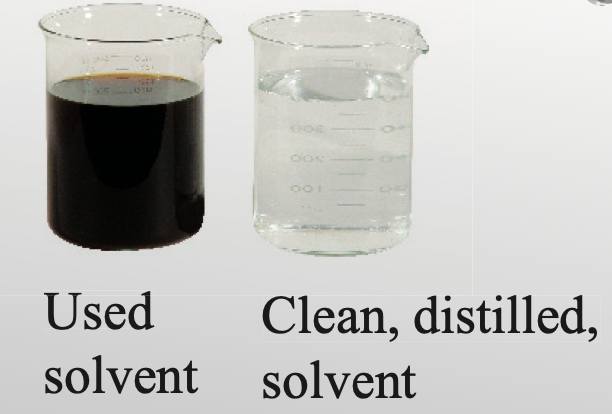

A Solvent Recyclers is at the heart of this sustainable practice. It is a sophisticated system designed to reclaim used solvents effectively. By reintroducing the clean, distilled solvents back into the operational cycle, a Solvent Recycler eliminates the necessity for unnecessary solvent purchases, which can drop by up to 90%, and slashes waste disposal costs by a similar margin. This not only enhances the profitability of businesses but also contributes significantly to environmental conservation.

On-Site Solvent Recycling

On-site recycling systems involve installing equipment within the facility to recover and reuse solvents. This method is particularly beneficial for industries that generate large amounts of solvent waste and require a quick turnaround.

One significant barrier to the broader adoption of on-site solvent recycling is the prevalent belief that it is too time-consuming and labor-intensive, a notion that has gained traction in the context of widespread labor shortages following the pandemic. However, as illustrated in the comparison below, on-site recycling involves fewer steps and consequently requires less labor than off-site handling.

Facilities that implement on-site recycling still need to procure, receive, and store virgin solvents, but this occurs much less frequently than in facilities that rely solely on off-site waste management. The extent of fresh solvent needed depends on the efficiency of your solvent distillation system, which can significantly reduce the man-hours devoted to managing new solvent supplies.

On-site recycling not only diminishes the frequency of solvent purchases but also substantially reduces the volume of solvent waste produced. Instead of sending all solvent waste off-site, you primarily dispose of the still bottoms—the residues left after distillation. The volume of waste shipped off-site is contingent on your distillation system’s efficiency. For instance, if a facility typically generates 100 drums of solvent waste monthly and outsources disposal, it maximizes labor dedicated to managing this waste. By recycling these 100 drums on-site with an 90% efficient system, only about 10 drums of waste need handling each month. This approach cuts the labor required for waste management and preparation by 90%, streamlining operations considerably.

Advantages of On-Site Recycling

- Cost-Effectiveness: Although initial setup costs can be high, on-site recycling significantly reduces the expenses related to purchasing new solvents and disposing of waste solvents.

- Immediate Reuse: Recycled solvents can be reintroduced into the production cycle almost immediately, increasing operational efficiency.

- Environmental Impact: Reducing the need for solvent disposal and the associated transportation decreases your company’s carbon footprint.

Implementing On-Site Recycling

Implementing an on-site system requires a detailed understanding of the types of solvents used, the volume of waste generated, and the specific recycling technologies that best fit the company’s needs. Common systems include distillation, filtration, and adsorption technologies.

Introducing Uni-ram’s Solvent Recyclers

Fortunately, achieving the full advantages of on-site solvent recycling without overextending your labor resources is possible. Uni-ram offers a series of solvent recyclers that operate continuously, using water-chilled distillation to recover up to 95% of the solvent with minimal daily intervention—just a few minutes per day from your staff. Depending on your setup, you can easily connect the recycler’s feed hose to a waste drum or tote, set the parameters, and then simply leave it to do its work. In certain configurations, the solvent waste can be piped directly into the Uni-ram recycler, with the recovered solvent automatically transferred to your bulk storage.

Uni-ram’s recyclers stand out from the competition by automating the removal of still bottom material, which is expelled as sludge directly into a waste drum, avoiding the unpleasant and time-consuming task of manual removal.

Investing in an on-site solvent recycler often implies a commitment to its maintenance and repair, which can be resource-intensive. However, Uni-ram alleviates this burden by offering complimentary routine maintenance and repair services. Should your recycler require any attention, assistance is readily available through the Uni-ram Local Dealer network. Understanding that modern facilities cannot afford extensive downtime, Uni-ram ensures your recycling operations are efficient and uninterrupted, handling maintenance so you don’t have to.

Conclusion

Choosing the right solvent recovery solution depends largely on your company’s specific needs, the volume of waste generated, and your sustainability goals. Both off-site and on-site recycling have their advantages, and in some cases, a combination of both might be the best approach. By investing in solvent recycling, companies not only adhere to environmental standards but also improve their bottom line.

The integration of solvent recycling into waste management strategies represents a pivotal step towards achieving sustainable industrial practices. By embracing “Solvent Recycling for Waste Management,” businesses can realize not only significant economic and operational benefits but also contribute meaningfully to environmental conservation. The call to action is clear: for a more sustainable and economically efficient future, solvent recycling should be at the forefront of business practices.

The URS500 Series, solvent recycler effectively reclaims used solvent for reuse and segregates solid waste like paint for disposal. With a Uni-ram solvent recycler, the operation becomes “Greener”. The facility can improve its Waste Generator Status with Environmental Agencies as used solvent transported off-site is reduced by approximately 90%. Solvent purchases typically drop by approximately 90% and the waste hauling charge also drops by approximately 90%. The 10% waste from recycling is considered hazardous unless the Disposal Service advises otherwise. Please check our product brochure for more details.

For more details on implementing these strategies in your solvent recycling practices, please feel free to contact us. We are here to provide additional information and guidance tailored to your specific needs and requirements.

In light of the imperative nature of addressing climate change, the reduction of industrial carbon emissions has transitioned from being a mere choice to an absolute necessity. Uniram Corp. provides eco-friendly Solvent Recyclers Solution, along with additional strategies, offering a comprehensive approach to attaining sustainability goals. Through the embrace of innovation, collaborative efforts, and a steadfast commitment to sustainability, industries can lead the way towards a greener and more sustainable future, concurrently enhancing their financial bottom lines.

Industries play a pivotal role in the collective pursuit of carbon neutrality and a healthier planet. By incorporating these strategies, you have the potential to substantially diminish your industrial carbon emissions footprint, actively contributing to the creation of a more sustainable industrial landscape. For further insights into these approaches and tailored solutions, please don’t hesitate to reach out to us. We are here to provide additional information and assistance to meet your specific needs and aspirations.