A Guide for SME Preparedness: Navigating a Future Shaped by Carbon Regulations

Introduction

As we navigate the evolving terrain of carbon emission regulations, it’s clear that businesses of all sizes are preparing for a future where strict rules will reshape how they operate and strategize. This article explores the impact of these regulatory changes and what they mean for various industries:

A Call for SME Readiness Amid Stricter Carbon Emission Standards

In North America and Europe, regulatory bodies are setting ambitious goals to reduce carbon footprints. The European Union’s “Fit for 55” initiative, aiming to reduce greenhouse gas emissions by 55% by 2030, represents a major shift with significant implications for SMEs, such as auto repair shops, which are deeply embedded in broad supply chains and indirectly impacted by emission costs. SMEs must prepare for these changes and proactively engage with the regulatory landscape to build resilience against evolving standards.

In-Depth Analysis: Challenges and Preparedness of SMEs

SMEs encounter distinct challenges in adapting to tighter regulations. From comprehending compliance demands to investing in green technologies, these businesses must actively tackle the complexities of transitioning to a low-carbon economy. Often lacking the resources and expertise of larger corporations, SMEs particularly need specialized support and guidance to navigate through these changes.

Economic and Environmental Implications

The consequences of failing to meet new standards can extend beyond financial penalties to include reputational damage and reduced competitiveness in the market. In industries like automotive manufacturing, where emission standards are critical, non-compliance can lead to substantial fines and loss of consumer trust. Embracing environmental responsibility is not only a moral duty but also a strategic necessity for businesses aiming to protect their financial interests and promote sustainable growth.

For example, British Energy, a UK power company in the early 2010s, faced market losses and regulatory challenges as it continued to rely on traditional energy sources despite stricter regulations. This resulted in financial strain and reputational harm as competitors moved towards cleaner energy, highlighting the risks businesses face when they do not adapt swiftly to regulatory changes.

As a response, SMEs should prioritize proactive steps and seek customized support to ensure they meet compliance and maintain resilience in this shifting regulatory environment.

Incorporating ESG: Boosting Business Value

Incorporating environmental, social, and governance (ESG) principles into business operations isn’t just about compliance—it’s about enhancing enterprise value and future-proofing business models. By aligning with ESG frameworks, businesses can attract investment, mitigate risks, and capitalize on emerging opportunities in a rapidly changing market landscape. You can review more information on United States Environmental Protection Agency (US EPA).

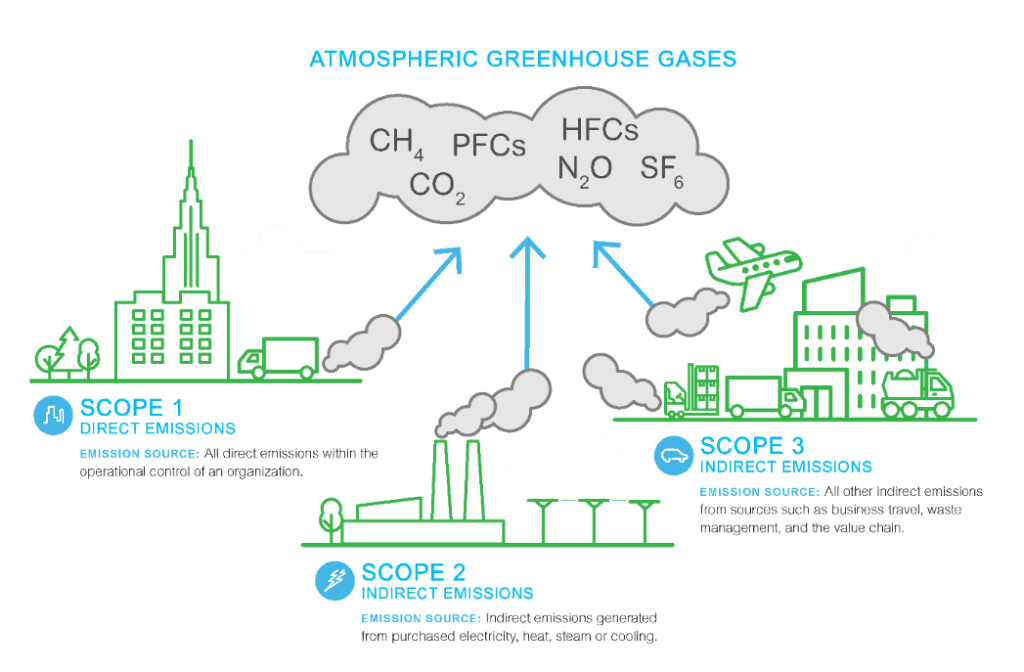

In the realm of ESG compliance, understanding and addressing Scope 1, 2, and 3 emissions are critical components of reducing carbon footprints.

Scope 1 & 2 Emissions:

These encompass direct and indirect emissions from a company’s operations and purchased energy sources, respectively. Strategies to reduce these emissions involve investing in energy-efficient equipment and transitioning to cleaner energy sources.

Scope 3 Emissions:

Indirect emissions throughout a company’s value chain are Scope 3 emissions. These are often overlooked but essential for comprehensive ESG reporting. Companies can address Scope 3 emissions by collaborating with suppliers and optimizing product lifecycle management.

The Importance of Scope 3 Emissions:

As regulatory bodies propose new climate disclosure rules, companies are recognizing the significance of accounting for Scope 3 emissions in their ESG initiatives.

ESG Integration and Scope 3 Emissions:

Companies are leveraging ESG principles to effectively address Scope 3 emissions by holding suppliers accountable and prioritizing partnerships with environmentally responsible suppliers.

Solvent Waste Handling and GHG Emissions:

Uni-ram solvent recycler offers a sustainable solution to mitigate GHG emissions in industries reliant on solvent use. Compared to traditional methods, on-site recycling minimizes the need for virgin solvent purchases, reducing both Scope 1 and Scope 3 emissions.

Navigating Through Innovation: Uni-ram’s Solvent Recycling Solution

Uni-ram’s solvent recycler is essential for companies committed to reducing both their direct and indirect emissions.If you’re dedicated to reducing both your own Scope 1 emissions and those of your customers, Uni-ram’s solvent recycler is indispensable. Research commissioned by the European Solvent Recycler Group in 2013 revealed that recycling mixed solvents like acetone, THF, MEK, TEA, and PERC can result in substantial reductions in greenhouse gas emissions, ranging from 46-92% compared to using virgin solvents. These savings stem from avoiding the production of virgin solvents and the disposal of solvent waste.

Uni-ram has revolutionized solvent recycling, offering a service that provides immediate savings without any upfront costs (Uni-ram Saving Calculator). Our partnership ensures that our success perfectly aligns with your focus on ESG mandates. With our solvent recyclers, we can restore your solvents to 99% virgin quality, reducing the need for new solvent purchases and hazardous waste shipments. This means you’ll have recycled solvent available whenever you need it, leading to significant reductions in your Scope 1 emissions and overall carbon footprint.

In the face of regulatory complexities, innovative solutions like Uni-ram’s advanced solvent recyclers offer a beacon of hope. By empowering businesses to recycle solvents on-site, Uni-ram not only reduces carbon emissions but also fosters resource efficiency and waste minimization. SMEs, such as auto repair shops, can leverage such technologies to achieve compliance without incurring prohibitive costs, thereby positioning themselves as leaders in sustainable practices and gaining a competitive edge in a carbon-conscious economy.

Conclusion

As we stand on the brink of a significantly more carbon-regulated future, the necessity for small and medium-sized enterprises (SMEs) to adapt has never been more crucial. The evolving landscape of environmental regulations demands that businesses, regardless of their size or sector, prepare to meet stricter standards that will inevitably shape their operational and strategic frameworks. This guide aims to not only illuminate the path forward but also equip SMEs with the necessary tools and knowledge to navigate these changes effectively.

The journey toward compliance is not merely about avoiding penalties but embracing an opportunity to pivot towards sustainable practices that can drive long-term growth and resilience. By understanding the nuances of the regulations, like the EU’s ambitious “Fit for 55” program, SMEs can begin to implement changes that will safeguard their future. Investments in cleaner technologies and processes, a deeper commitment to ESG principles, and a proactive approach to emissions management are integral steps that can transform potential challenges into competitive advantages.

Moreover, the transition to a low-carbon economy offers a chance for SMEs to innovate, attract new investments, and enhance their market position. By fostering collaborations that extend across their supply chains, SMEs can leverage collective expertise and resources to achieve more significant impacts in emission reductions. Additionally, engaging with specialized support and leveraging tailored guidance are critical for SMEs to navigate the complex regulatory environment without being overwhelmed by its demands.

The URS500 Series, solvent recycler effectively reclaims used solvent for reuse and segregates solid waste like paint for disposal. With a Uni-ram solvent recycler, the operation becomes “Greener”. The facility can improve its Waste Generator Status with Environmental Agencies as used solvent transported off-site is reduced by approximately 90%. Solvent purchases typically drop by approximately 90% and the waste hauling charge also drops by approximately 90%. The 10% waste from recycling is considered hazardous unless the Disposal Service advises otherwise. Please check our product brochure for more details.

For more details on implementing these strategies in your solvent recycling practices, please feel free to contact us. We are here to provide additional information and guidance tailored to your specific needs and requirements.

In light of the imperative nature of addressing climate change, the reduction of industrial carbon emissions has transitioned from being a mere choice to an absolute necessity. Uniram Corp. provides eco-friendly Solvent Recyclers Solution, along with additional strategies, offering a comprehensive approach to attaining sustainability goals. Through the embrace of innovation, collaborative efforts, and a steadfast commitment to sustainability, industries can lead the way towards a greener and more sustainable future, concurrently enhancing their financial bottom lines.

Industries play a pivotal role in the collective pursuit of carbon neutrality and a healthier planet. By incorporating these strategies, you have the potential to substantially diminish your industrial carbon emissions footprint, actively contributing to the creation of a more sustainable industrial landscape. For further insights into these approaches and tailored solutions, please don’t hesitate to reach out to us. We are here to provide additional information and assistance to meet your specific needs and aspirations.