Description

U103-S Pressure Sand Blaster – Dirt, Rust, Paint and Unwanted Deposits to prepare surface for repair and painting.

The abrasive from the high flow, 10 Gallon, 100 pound U100-S penetrates the deepest pitted area to remove dirt, rust, paint and unwanted deposits. Readies the surface for priming and filler. Ideal for refinishing vehicles, boats, monuments, brick buildings and industrial equipment.

MODELS

Economical U100-S U103-S

Complete with 8 ft, 4 ply, heavy duty

1/2” hose, clamped securely to Blast Gun.

Complete with: 10 ft, 4 ply heavy duty 1/2” hose, quick disconnect fittings on hose and blaster to eliminate a blockage, pressure regulator, moisture filter, 3 seal blocks and 3 1/8” ceramic nozzles.

Operation

Filling tank with Abrasive is quick and easy:

• Pour abrasive with ease into Built-In Funnel

at top of tank.

• Return maintenance free Removable Filler Plug and apply air pressure, which forces plug upward and seals tank.

Operational Features

- Working Pressure: Maximum operating pressure is 125 PSI.

- Pressure Release Valve: Calibrated to release at 140 PSI to ensure safety during operation.

- Hose Type: Heavy duty 4-ply hose for durability and long-lasting use.

- Abrasive Flow Control Valve: Allows for precise adjustment of the sand flow, ensuring efficient use of materials and effective cleaning.

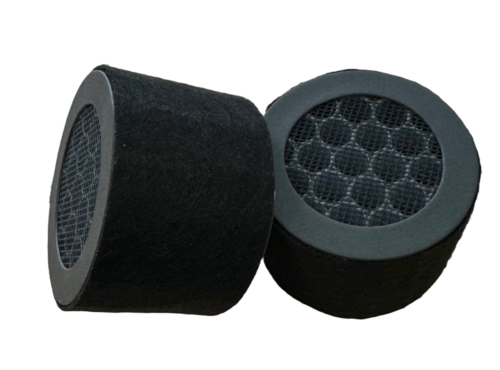

Blasting Abrasive

• Open Air Inlet Shut-Off Valve all the way on side of tank.

• Adjust Abrasive Control Valve on bottom of tank. This regulates the mixture of air to abrasive.

• Squeeze Safety Shut-Off Valve to activate flow of abrasive.

Abrasives include: glass beads, metal shot, aluminum oxide and nut shells.

NOTE: Uni-ram recommends against the use of coal and other slag products that may contain and expose the user to intrinsically hazardous dusts, such as beryllium.

Appropriate protective equipment should be worn at all times during blasting operations.

The Safety Shut-Off is an innovative Uni-ram design. Releasing lever terminates abrasive flow for operator safety.