Description

The BB30CE Solvent Recycler provides a shop with clean recycled solvent every day. Typical solvents include paint thinner, acetone and varsol. With a Uni-ram solvent recycler the shop’s environmental footprint shrinks and the shop saves money. Solvent purchases and the cost for used solvent transported off-site drop by approximately 90%.

The BB30CE provides 25 L of clean recycled solvent from each recycling batch.

Capacities For Industrial Solvent Recyclers

| BB30CE | CB70CE | DB100CE | |

| Capacity | 25L | 60 L | 75 L |

| Input | 220-240 V | 220-240 V | 220-240 V |

| Heating Element | 2,100 W | 3,400 W | 3,400 W |

Features:

- Distillation by vaporization and condensation.

- Power Supply: 220-240V, 20A, 2100W heating element

- Direct electric heating with no oil to change or refrigerant to service for lower maintenance.

- Sophisticated solid-state microprocessor controls the work flow and continuously monitors operating parameters. Many built-in safety programs. The computer display (LCD) shows the set point and real-time temperatures at the tank and condenser. Special features in the computer menu allow for:

1) lowering of the heater wattage to make the boiling phase less vigorous; this is important for low boiling point solvents such as acetone.

2) increasing the post heat time to make the solvent residue dryer thus increasing recycling efficiency.

- The temperature set points can be adjusted precisely in one degree increments.

- Complete self diagnostic system. Sensors monitor the operating system; Faults are described using messages in English for easy diagnostics.

- Dual pump transfer system to pump dirty solvent directly into the distillation tank and pump clean recycled solvent from the recycler to a clean drum.

- Automatic or timed shut off.

- Outer cabinet, cover and lid are made from corrosion resistant 304 grade stainless steel for long life.

- High efficiency condenser is air cooled by motor driven fan. Constructed from 316 grade stainless steel.

- Complete with 3 heat resistant liner bags to capture residue and 2 lid gaskets.

Options:

- P Vacuum Assist

- M Pneumatic Drum Mixer

- L Pat-Light with Buzzer

- A Rapid Tank Cooling

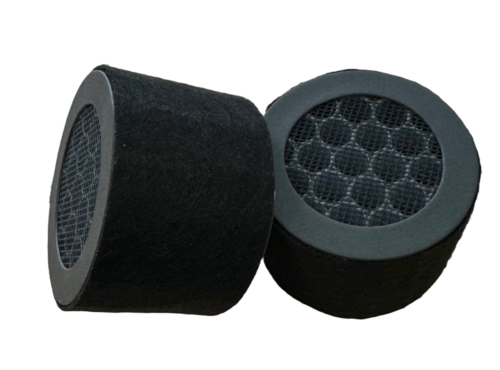

- W Filter system for water recycling

- G Recycle solvent and water mixture

Safety:

- Certified to IECEX and ATEX safety directives by SGS Fimko Oy with compliance to ATEX directive Group II Category 2G Ex db ib IIA T2 Gb. for use with solvent in zone 1. ATEX certification number is Baseefa11ATEX0118 and IECEX certification number is BAS 11.0057.

- Additional safety features include the lid pressure relief system, safety cover and optional lid lock.

Operation:

Turn the Timer to pump 25 L of dirty solvent into the bag in the distillation tank. Press Start to turn on the heating element. Solvent vaporizes, leaves the distillation tank to flow through the condenser to the receiving pail. An electric fan cools the vapor to a liquid as it flows through the condenser. The recycling time is typically 4-6 hours. The residue that remains in the heat resistant liner bag in the distillation tank is transferred to a waste drum for later disposal by a licensed waste hauler (as required in many jurisdictions).

Typical Applications

- Reclaim lacquer thinners, acetone and gun wash solvents used to remove paint and debris from spray guns and other spray equipment.

- Reclaim acetone used to clean equipment used in making fiberglass products.

Typical users:

- Industrial Paint Shops, Fiberglass Fabricators, Printers, Metal Fabricators.