- Home

- All products

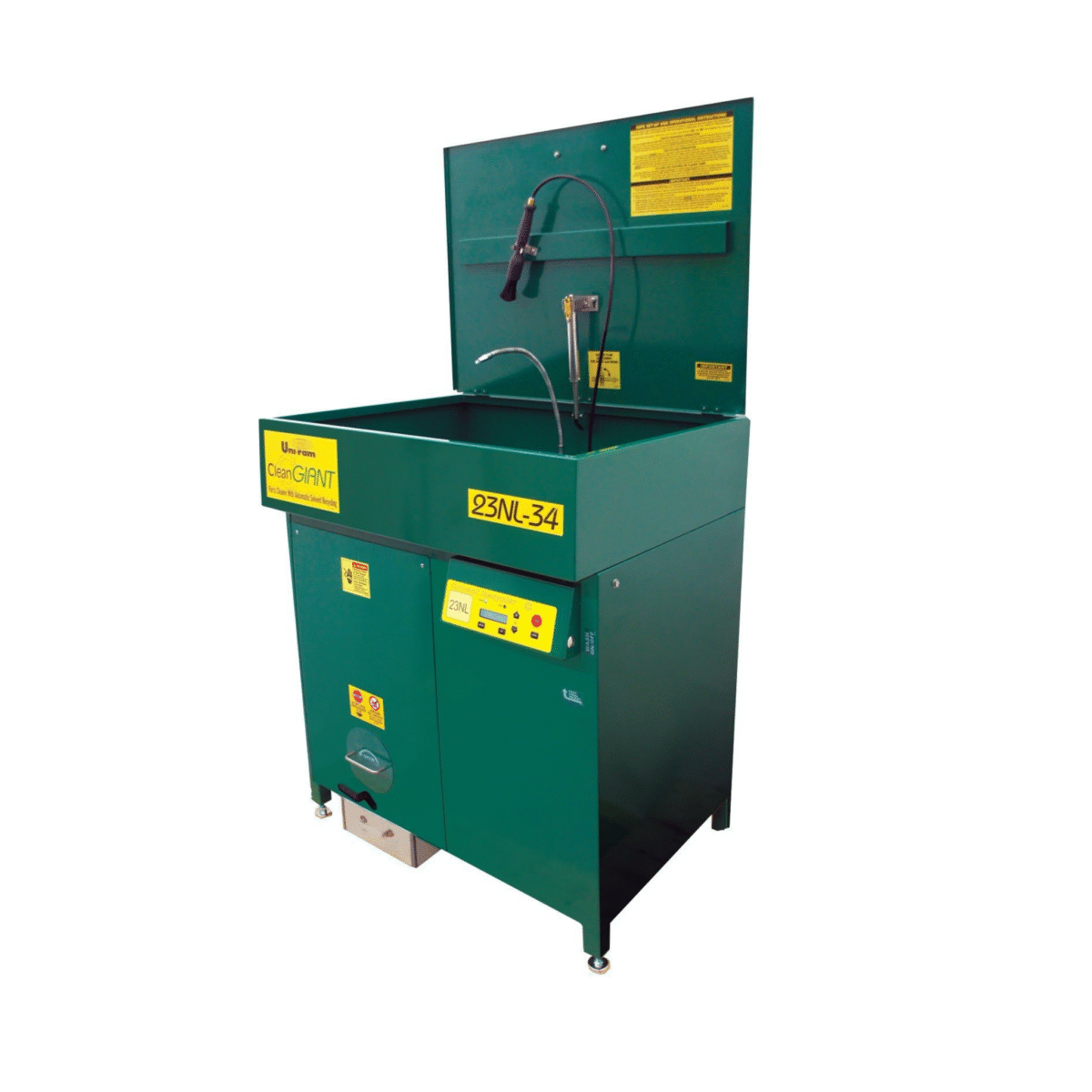

- 23NL Series Part Washer With Solvent Recycler

SKU:

23NL Series Part Washer With Solvent Recycler

$6,710.75 – $7,633.00Price range: $6,710.75 through $7,633.00

The 23NL Series Parts Washer with built-in solvent recycler provides fast, efficient parts cleaning using a flow-through brush and flexible spigot. At the push of a button, dirty solvent is drained and automatically replaced with 5 gallons of clean, recycled solvent, ensuring fresh solvent is available daily. The integrated solvent recycler processes used solvent in about 4 hours, cutting solvent purchases and disposal costs by up to 90% while reducing the facility’s carbon footprint. Designed for durability and ease of service, it features a stainless steel clean tank, LCD-controlled diagnostics, and a certified safety system (UL2208/CSA).

Specifications

Product Description

Applications

Additional Information

Specifications

- Electric Supply: 120v. AC, Single Phase, 60Hz, 1.5Kw, 15A. (Use 20A dedicated line.)

- Washing Tools: A Flow-through Brush and a Flexible Spigot, each with flow control valve.

- Vacuum Pump: Uni-ram Vacuum Pump with a Metal Impeller, 120v, 4.6A, 1/3HP, 3,500rpm.

- Solvent Pumps: Wash Pump and Transfer Pump, 120v. AC, 70W, each

- Heaters: 2 Cartridge Immersion Heater, 120v, 475w each, Stainless steel heath.

- Control System: A computer board with 32-character LCD, Buzzer, 2 LEDs, and 6 Keys.

- Control Sensors: Two thermo-couples, two thermostats, Vacuum Sensor, Level Sensor

- Duty Solvent Tank: Powder-painted steel, 15 Gallon capacity, Standard fill of 5 Gallons 18.9Liters) with SS Cartridge Filter on Inlet port.

- Distillation Tank: Galvanised steel, 14 Gallon capacity, Standard fill of 6 gallons (22.7 Liters), Debris Drain Ball Valve, 4.25” Clean-out Cap.

- Clean Solvent Tank: Stainless Steel 304, 30 Gallon (113.5 Liters) capacity.

- Debris Drawer: Galvanised steel, 1.05 Gallon Capacity (4 Liters), Removable.

- Facility: Connector for Optional Foot Pedal for hands free operation.

Safety Note: For use with “non-flammable” solvents only, defined as solvents with a flash point temperature above 100°F (37.8°C) and a self-ignition temperature above 392°F (200°C).

Product Description

Uni-ram 23NL Series – Part Washer with Integrated Solvent Recycler

Premium All-in-One Cleaning and Recycling System

The 23NL Series Part Washer from Uni-ram offers a complete solution for parts washing and solvent recycling, engineered for performance, safety, and sustainability. With automated cleaning tools and a built-in solvent recycler, the system reduces solvent consumption by up to 90% while delivering consistent, clean solvent every day.

Key Features:

-

Top-Performance Cleaning Tools

Equipped with a flow-through brush and flexible spigot, each with a dedicated flow control valve, providing fast, efficient, and targeted cleaning. -

Automatic Solvent Recycling

Dirty solvent is automatically transferred for distillation and replaced with 5 gallons (18.9 L) of clean solvent at the press of a button.

The cleaning cycle is only interrupted for 4 minutes during solvent exchange. -

Multi-Tank System for Efficient Workflow

-

Clean Solvent Tank: 30-gallon (113.5 L) 304 stainless steel

-

Duty Solvent Tank: 15-gallon (powder-coated steel), with SS cartridge filter

-

Distillation Tank: 14-gallon galvanized steel with 6-gallon fill, clean-out cap, and debris drain

-

Removable Debris Drawer: 1.05-gallon galvanized steel (4 L)

-

-

Advanced Control & Safety Features

-

LCD with 32-character readout

-

Integrated buzzer, 2 LED indicators, and 6-key input

-

Built-in safety diagnostics, vacuum sensor, dual thermostats, dual thermocouples, and level sensor

-

Safety lid switch halts pump operation when lid is raised

-

Optional foot pedal connector for hands-free control

-

-

Quick Servicing

Tanks can be removed without detaching the wash sink

Entire unit is portable via forklift or pallet truck

Technical Specifications:

-

Electric Supply: 120V AC, Single Phase, 60Hz, 1.5KW, 15A (Use 20A dedicated line)

-

Vacuum Pump: 1/3 HP Uni-ram pump, 4.6A, 3,500 RPM, metal impeller

-

Wash & Transfer Pumps: Two 120V AC, 70W pumps for solvent circulation

-

Heaters: Two stainless steel cartridge immersion heaters (120V, 475W each)

-

Control System: Microprocessor board with LCD, buzzer, LEDs, and keypad

-

Control Sensors: 2 thermocouples, 2 thermostats, vacuum and level sensors

Environmental & Operational Benefits:

-

Reduces solvent waste by up to 90%

-

Minimizes off-site hazardous waste hauling

-

Cuts solvent purchase costs

-

Enhances facility sustainability and safety

-

ETL Certified to UL2208 and CSA 22.2 No. 88

Why Choose the 23NL Series?

The Uni-ram 23NL Series Part Washer is the smart, eco-conscious choice for facilities looking to streamline operations, reduce solvent costs, and meet environmental standards. With robust construction, intelligent automation, and effortless serviceability, it stands out as the industry’s most complete parts washing and solvent recycling system.

👉 Learn More: Waste Recovery vs. Traditional Washers

📧 Contact: sales@uniram.com | 🌐 Visit: www.uniram.com

Applications

Applications:

The Uni-Ram 23NL Series Parts Washer is ideal for recycling solvents used in a variety of industries, including:

- Manufacturing

- Coating

- Automotive

- Metal Finishing

- Printing & Ink

- Electrical

- Oil & Gas

- Fiberglass

- Furniture & Cabinetrv

- Aerospace &Marine

- and more

Additional Information

Additional Models:

MODELS SINK SIZE (“)

23NL-34 34 W x 28 D x 8 H

23NL-42 42 W x 28 D x 8 H

Model Dimensions and Weight:

- Uniram 23NL-34: Sink Size: 34″ W x 28″ D x 8″ H | Dimensions: 34″ W x 28″ D x 40″ H | Weight: 272 lb

- Uniram 23NL-42: Sink Size: 42″ W x 28″ D x 8″ H | Dimensions: 42″ W x 28″ D x 40″ H | Weight: 302 lb

Safety Note: For use with “non-flammable” solvents only, defined as solvents with a flash point temperature above 100°F (37.8°C) and a self-ignition temperature above 392°F (200°C).

Related Products

$4,395.00 – $5,165.00Price range: $4,395.00 through $5,165.00