Save Money With Uni-ram Solvent Recyclers.

Our customers in USA typically see a full return on their investment within just 12 months!

Discover the Most Advanced Solvent Recycler for Cost-Saving and Eco-Friendly Operations

Uni-ram’s state-of-the-art solvent recovery systems are engineered to help businesses significantly reduce solvent waste, cut down disposal costs, and reclaim up to 95% of used solvent. Our systems are trusted by thousands of companies across the globe, delivering up to 90% savings on operational costs while supporting strict environmental compliance standards.

Whether you’re operating in automotive refinishing, industrial manufacturing, metal fabrication, or printing, Uni-ram offers a reliable and proven solution to keep your operations cost-efficient and sustainable.

Why Choose Uni-ram Solvent Recycling Equipments?

♻️ Reduce Solvent Waste: Reclaim used solvent for reuse, minimizing hazardous waste generation.

💰 Cut Disposal and Purchasing Costs: Lower your need for virgin solvent and reduce off-site waste disposal expenses.

🌱 Support Environmental Goals: Align with sustainability targets and environmental regulations.

🔧 Customized Solutions: Choose from standard models or request tailored solvent recycling systems for your unique needs.

Industry-Proven Performance

Uni-ram Corporation is a global leader in solvent recycler and recovery technology. Since 1980, we’ve shipped over 160,000 solvent recyclers and spray gun washers to businesses in over 50 countries. Our award-winning equipment is built for reliability, efficiency, and long-term value—designed to meet the demands of modern industrial environments.

Stay Competitive with Uni-ram Solvent Recovry Unit

Our Solvent Recovry Unit help you stay competitive by minimizing solvent waste costs and supporting your company’s environmental sustainability goals. No matter what solvent you use—acetone, lacquer thinner, or other common solvents—we provide a solution that delivers measurable ROI while reducing your environmental footprint.

Get Started Today

Ready to cut costs and go green? Contact Uni-ram today to find the right solvent recycler for your business.

📞 Call us at 1-800-417-9133 or visit our contact page to speak with a specialist. Let us help you implement a safe, dependable, and eco-friendly solvent recovery system tailored to your operation.

Submit A Purchase Order

Need a custom quote, or ordering large quantities of Uni-Ram products? Please contact Uni-ram sales team for special pricing today, Toll-Free 1-800-417-9133.

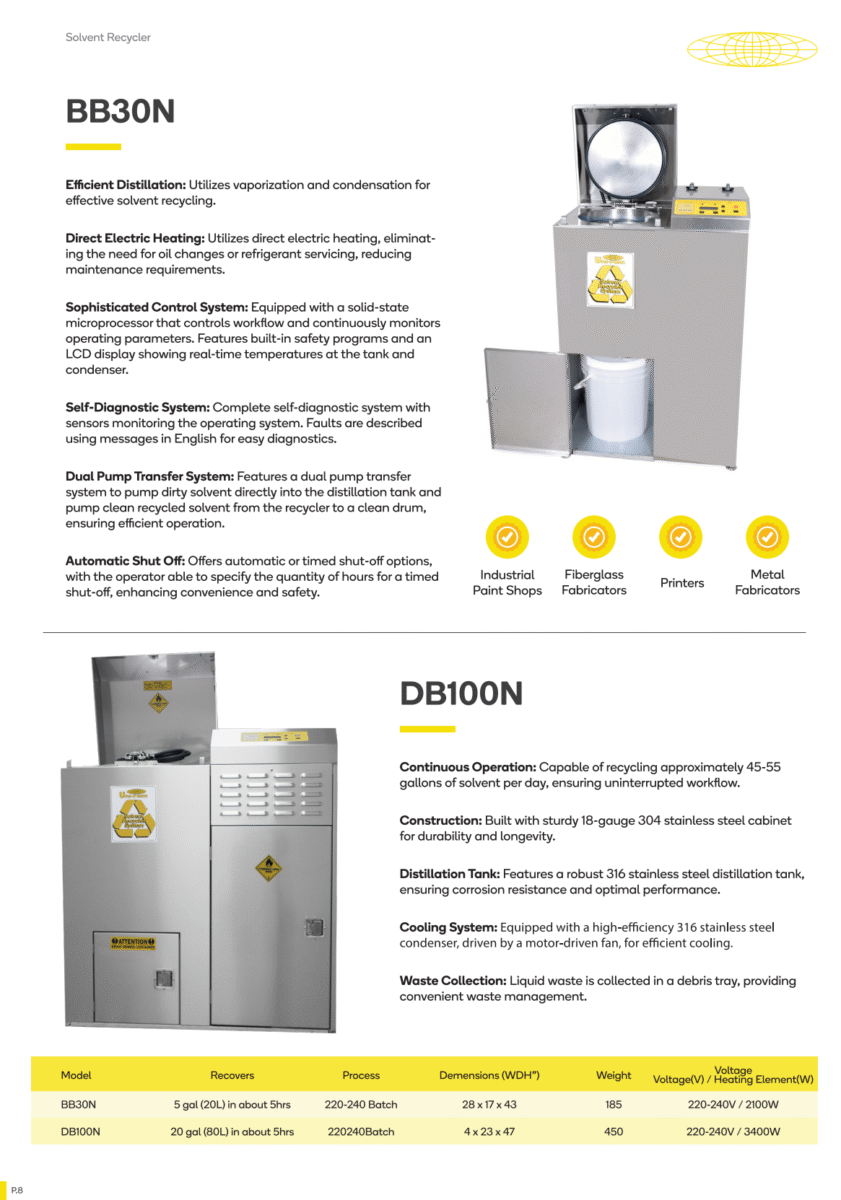

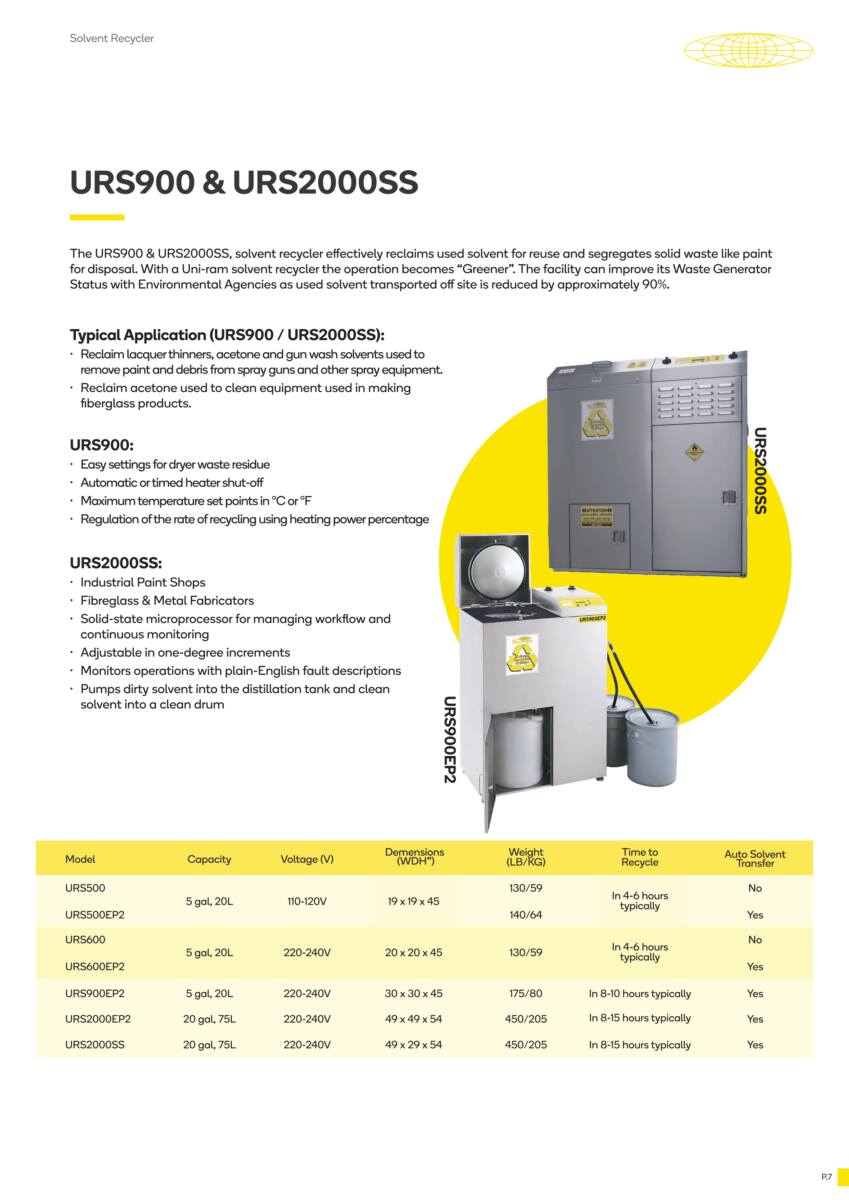

Welcome to our dedicated page for Solvent Recyclers, the heart of our solvent recovery solutions. As a leader in solvent recycling technology, we offer a range of high-quality solvent recycling equipment designed to meet the needs of various sectors, including automotive, industrial, and painting industries. Our advanced Solvent Recycling Systems, including the popular Uni-ram Solvent Recycler URS2000SS, are engineered to provide efficient and reliable performance, ensuring that your operations are both cost-effective and environmentally friendly.

Why Use a Solvent Distillation System (Solvent Recovery System)?

Solvent Distillation System (Solvent Recovery System), also known as Solvent Recyclers/Solvent Distillers, are designed to remove soils, debris, and oils from used cleaning solvents through a process called distillation. This allows the cleaned solvent to be reused multiple times, reducing the need for new solvent purchases by over 90% and cutting down chemical waste disposal costs by a similar margin. Here’s why investing in a solvent recovery system is a smart move:

- Cost Savings: Chemical disposal can be unexpectedly expensive. By using a solvent recycler, businesses can drastically reduce both disposal costs and the costs associated with purchasing new solvents.

- Environmental Impact: Reducing chemical waste is not only cost-effective but also environmentally responsible. A solvent recovery system minimizes the environmental footprint of industrial processes.

These systems can recycle and recover a wide range of solvents used in various industries, including:

- Paint body shops

- Automotive factories

- Collision repair shops

- Oil & gas industries

- Energy industries

- Metalworking industries

- Chemical industries

Moreover, Uni-ram’s URS500 & 600 series solvent recyclers are specifically designed to ensure safety when handling flammable solvents.

Optimize Your Processes with High-Performance Thinner Recycling Machine

Uni-ram Solvent Recycling Equipments are designed to help businesses reclaim and reuse solvents effectively, reducing waste and saving on solvent purchases. Each solvent recycling machine utilizes cutting-edge technology to distill and purify solvents from contaminants, delivering clean, reusable solvents that maintain high-performance levels.

Customers we proudly serve around the world

Get started today

Talk to the Uni-Ram sales team to learn about our products.

Save Money With Uni-ram Industrial Solvent Recovery Solutions

Solvent distillation is a powerful method used across industrial applications to purify, recover, and recycle solvents. Whether the goal is to create a highly refined product or reclaim usable material from contaminated waste, the solvent distillation process offers an efficient, cost-saving, and eco-conscious solution.

What Is the Solvent Distillation Process?

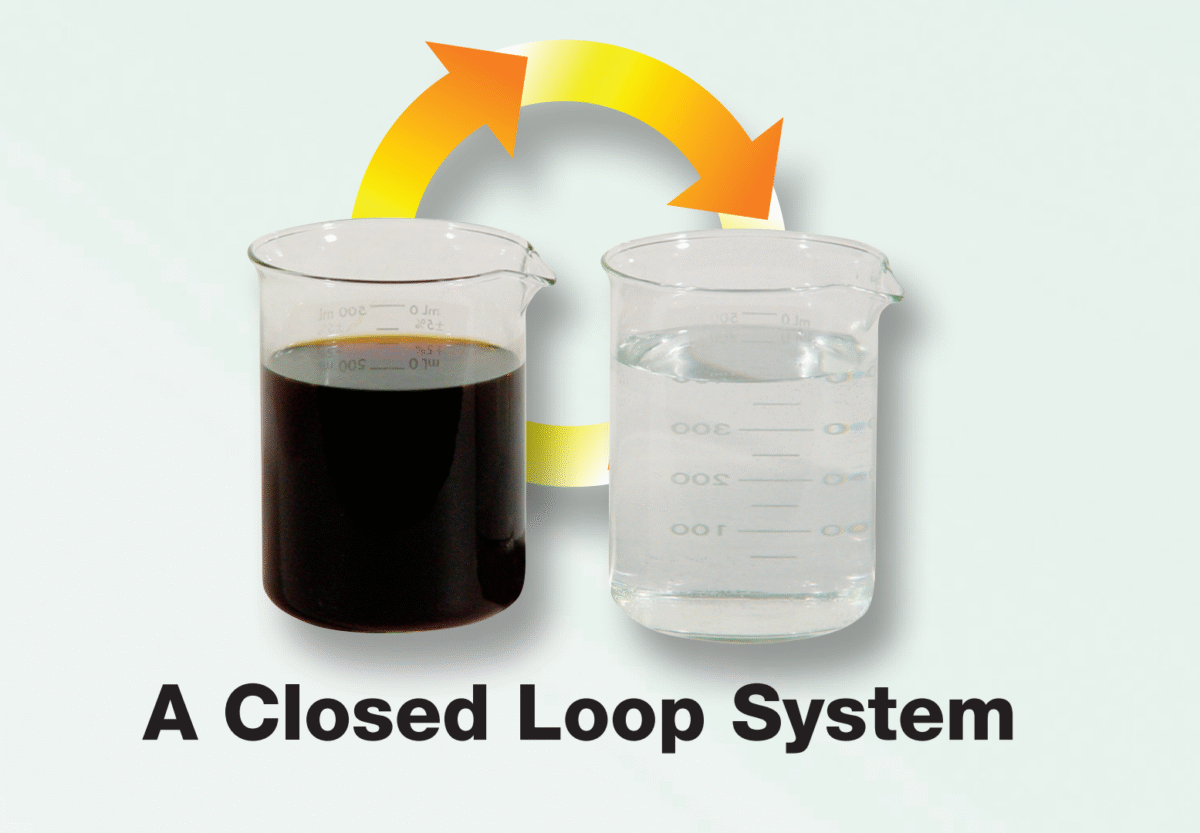

Distillation is a thermal separation technique that relies on the varying boiling points of substances in a liquid mixture. It consists of two essential steps:

Vaporization: The mixture is heated, causing the component with the lowest boiling point to evaporate.

Condensation: The vapor is captured and cooled, converting it back into a purified liquid while separating it from other contaminants or higher-boiling compounds.

This process is widely adopted in chemical, pharmaceutical, and industrial sectors to ensure precision purification and recovery.

How Do Solvent Distillers Work?

Solvent distillers, also known as solvent recyclers or solvent recovery systems, use the principles of distillation to separate reusable solvents from contaminated waste. During the process, used solvent is heated until it vaporizes, leaving behind residues like paint sludge, oils, or other impurities. The vapor is then condensed into clean solvent, ready for reuse.

Why Use a Solvent Distillation System?

A Solvent Distillation System enables companies to recycle and reuse solvents rather than continuously purchasing new product and disposing of contaminated waste. The benefits are substantial:

✅ Cost Savings: Cut new solvent purchases and hazardous waste disposal costs by up to 90%.

✅ Eco-Friendly: Reduces your environmental impact and supports compliance with local waste regulations.

✅ High Efficiency: Recover solvents with purity rates as high as 95–98%.

✅ Enhanced Safety: Systems like Uni-ram’s URS500 and URS600 series are engineered to handle flammable solvents safely and reliably.

Industrial Solvent Recovery Applications

Uni-ram’s Solvent Recovery Systems are trusted across diverse industries, including:

- Chemical Industry Solvent Recovery

- Aerospace Industry Solvent Recovery

- Battery Production Solvent Recovery

- Boat Manufacturer Solvent Recovery

- Energy Industry Solvent Recovery

- Fiber Glass Solvent Recovery

From large manufacturing plants to smaller paint shops, any business using cleaning solvents can benefit from solvent recycling.

A Sustainable Future with Uni-ram Solvent Recyclers

Implementing a solvent distillation system is not only a smart business decision—it’s a commitment to sustainability. With Uni-ram’s proven technology, thousands of businesses worldwide have already reduced solvent consumption, minimized hazardous waste, and improved operational efficiency.

Get in touch today to learn more about our industry-leading Solvent Distillation Systems and how your operation can start saving money while protecting the environment.