- Home

- All products

- URS900 Solvent Recyclers

SKU:

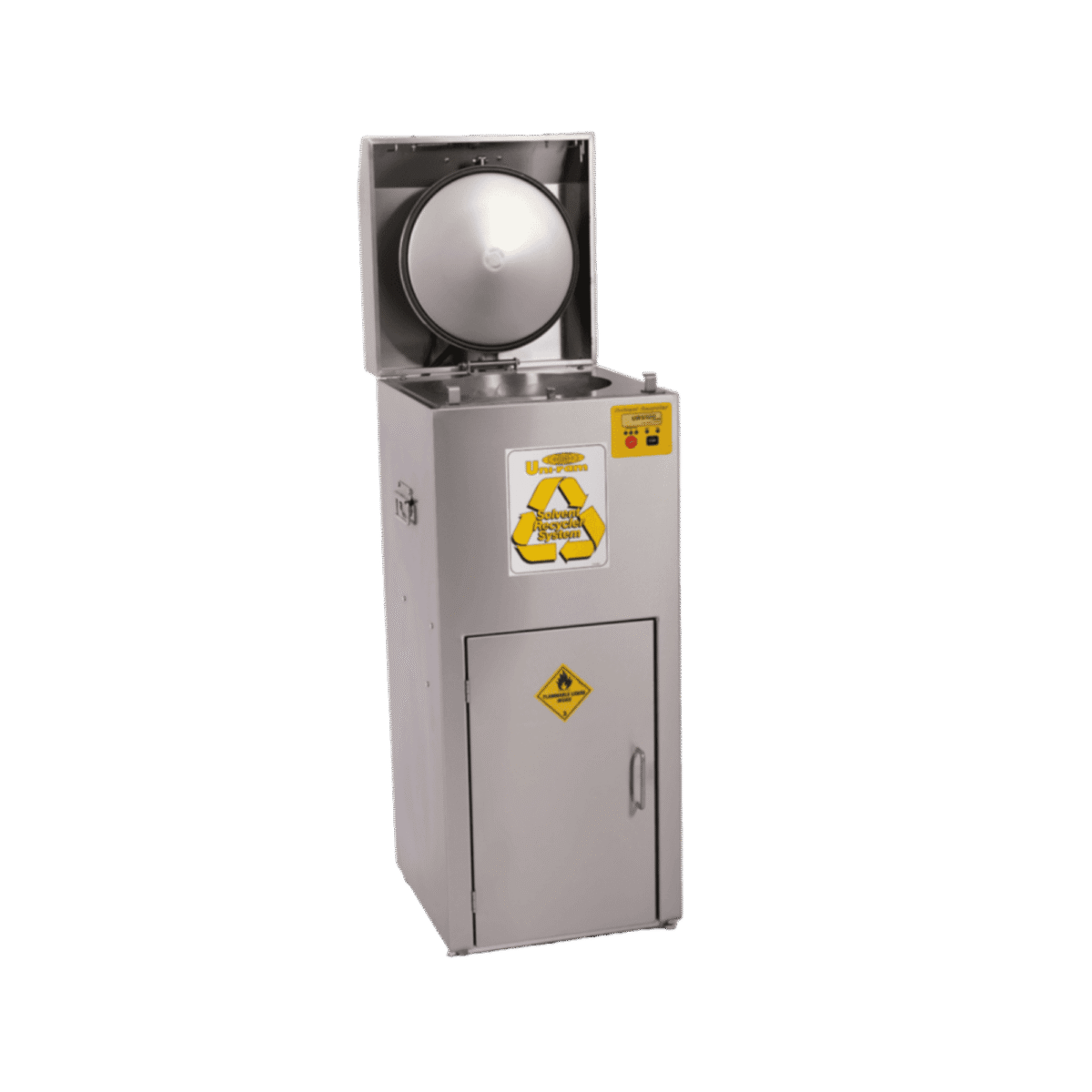

URS900 Solvent Recyclers

$7,272.00 – $11,268.00Price range: $7,272.00 through $11,268.00

The Uni-Ram URS900 Solvent Recycler processes 6.6 gallons of solvent per batch with a 220-240V, 2100W heater, completing each cycle in 4-6 hours. Designed for versatility, it includes advanced digital controls for easy operation and maintenance, along with robust safety features to ensure reliable solvent recycling across various applications.

Specifications

Product Description

Applications

Additional Information

Specifications

- Speed: 4-6 hrs.

- Power Supply: 220-240V, 2100 W heater.

- High efficiency copper condenser (stainless steel condensers are available).

- Digital display with an easy to use menu.

- Microprocessor: Controls work flow. Performs self-diagnostics explained with plain-English messages.

- Automatic or timed shutoff.

- Distillation by vaporization and condensation

- Outer cabinet and lid are made from 304-grade stainless steel for long life.

- Sophisticated solid-state microprocessor controls the work flow and continuously monitors operating parameters. Complete with a digital self-diagnostic system.

- Direct electric heating with no oil to change or refrigerant to service for lower maintenance.

- High efficiency copper condenser, air cooled with motor driven fan; a stainless steel condenser is also available on model

Product Description

The Uni-Ram URS900 Solvent Recycler efficiently recycles 6.6 gallons of solvent per batch using a 220-240V, 2100W heating system, with each cycle completed in 4 to 6 hours. Engineered for versatility, it features advanced digital controls for simplified operation and maintenance, along with enhanced safety systems for dependable performance in diverse environments.

Crafted from durable stainless steel and powered by direct electric heat, the URS900 is ideal for recycling solvents such as paint thinner, gun wash, and acetone. Certified for Class I, Division I environments and suitable for unattended use, this unit helps auto shops reduce solvent costs and hazardous waste by up to 95%—a smart, sustainable solution for modern shop operations.

Key Features

- High limit heater thermostat

- Condenser temperature monitor

- Inner lid and outer safety cover for distillation tank

- Fan motor thermostat with automatic reset

- Tank lid with built in Pressure relief valve

- Safe electronic circuitry

- Tank temperature sensor w/micro processor control

- Safety cycle limit timer (6 hour duration)

- Solvent receiver pail stored inside recycler cabinet

Applications

The Uni-Ram URS900 6.6 Gallon 240V Aluminum Solvent Recycler w/ Digital Display can be used to recycle a variety of solvents, including:

- Acetone

- Alcohol

- Ethyl Ether

- Toluene

- Xylene

- Methanol

- Water

Benefits

The Uni-Ram URS900 6.6 Gallon 240V Aluminum Solvent Recycler w/ Digital Display offers a number of benefits, including:

- Save money by recycling solvents

- Reduce waste disposal costs

- Protect the environment by recycling solvents

- Improve safety by reducing the risk of fire and explosions

- Extend the life of your solvents

Specifications

- Tank Capacity: 6.6 US Gal (25 litres)

- Speed: 6.6 US Gal in about 4-6 hours

- Solvent Transfer: Manual transfer

- Air Pressure: Not applicable

- Power Supply: 220/240V, 2200W, 9.3A

- Heater: 2100W

Enhanced Control Features and Digital Display

The Uni-Ram URS900 6.6 Gallon 240V Aluminum Solvent Recycler w/ Digital Display features a number of enhanced control features and digital display that make it easy to use and maintain. These features include:

- Easy settings for dryer waste residue

- Automatic or timed heater shut-off

- Maximum temperature set points in ° or °F

- Regulation of the rate of recycling using heating power percentage

URS900EP2 solvent recycler

The URS900EP2 solvent recycler provides a shop with clean recycled solvent every day. Typical solvents include paint thinner, gun wash solvent and acetone. With a Uni-ram solvent recycler the shop’s environmental footprint shrinks and the shop saves money. Solvent purchases and the cost for used solvent transported off-site drop by approximately 90%.

The URS900EP2 provides 6.6 gal of clean recycled solvent from each recycling batch.

| FEATURE | URS900EP2 | URS500 |

| Voltage Input | 220-240V | 110-120V |

| Heating Element | 2100 W | 1500 W |

| Tank Capacity | 5 gal, 25L | 5 gal , 19L |

| Computer display with menu showing additional features | Yes | No |

The URS900EP2 is for owners that want features not offered on the basic URS500 solvent recycler. Features on the URS900EP2, not on the URS500 are:

- Recycling is faster with the URS900EP2 due to a 2100W heating element vs 1500W heating element on the URS500. It also has a larger cooling condenser.

- Sophisticated solid-state microprocessor controls the work flow and continuously monitors operating parameters. The computer display (LCD) shows the set point and real-time temperatures at the tank and condenser. Special features in the computer menu allow for:

1) lowering of the heater wattage to make the boiling phase less vigorous; this is important for low boiling point solvents such as acetone.

2) increasing the post heat time to make the solvent residue dryer thus increasing recycling efficiency.

- Complete self-diagnostic system; sensors monitor the operating system; faults are described in English messages for easy diagnostics. Faults are indicated by flashing lights on the URS500.

- Odometer logging to tell how much solvent has been processed and money saved.

Safety Features:

- Certified to UL safety standard 2208 and CSA standard 22.2 no. 30 and 88 by ETL for use with solvents in Class 1, Division 1, group D locations. UL2208, with many built in safety programs, is the safety standard for solvent recyclers.

- Additional safety features include the lid pressure relief system, safety cover and optional lid lock.

The work shop of all collision repairs shop is classified as a class 1 division 2 by the National Electrical Code, due to the intermittent presence of solvent vapors. The paint mixing room is classified as the more stringent class 1 division 1 area, as solvent vapors are normally present. Uni-ram solvent recyclers are approved for use in all collision repair shops, other class 1 division 1 and 2 locations and non classified locations.

IMPORTANT SAFETY AND USAGE ADVISORY

Do not recycle solvents that includes Nitrocellulose due to its low auto ignition temperature and Peroxides due to its thermal decomposition. Check the Safety Data Sheet of both the solvent and waste material for the presence of these 2 substances.

- Shipping Dimensions: 30″ w x 20″ d x 45″ h.

- Shipping Weight 150 lb.

- Product Dimensions: 28″ w x 17″ d x 43″ h.

Applications

Applications:

The Uni-Ram URS900 220-240V, 6.6 Gallon Solvent Recycler is ideal for recycling solvents used in a variety of industries, including:

- Manufacturing

- Coating

- Automotive

- Metal Finishing

- Printing & Ink

- Electrical

- Oil & Gas

- Fiberglass

- Furniture & Cabinetrv

- Aerospace &Marine

- and more

The Uni-Ram URS900 6.6 Gallon 240V Aluminum Solvent Recycler with Digital Display can be used to recycle a variety of solvents, including:

- Acetone

- Alcohol

- Ethyl Ether

- Toluene

- Xylene

- Methanol

- Water

Additional Information

Additional Models

URS URS900EP2:

Is the same as URS900 except dirty solvent is pumped directly into the distillation tank and clean recycled solvent is pumped from the receiving pail to an external clean container. Pumps are activated by turning a timer.

Minimize Waste Generation – For use with Paint Thinner, Lacquer Thinner, Heptane, Toluene, Gun Washer Solvent, Xylene, Acetone, Methanol, Isopropylalcohol.

Easy to Operate – Press Start: the solvent vaporizes and condenses automatically. Clean, pure solvent collects in receiving pail inside the recycler. Residue remains in a heat resistant bag in tank. Dirty Solvent can be recycled. Uni-ram offers a family of Solvent Recyclers.

Health and Safety Features – Certified to UL Standard 2208 and CSA Standard 22.2 No. 30 and No. 88 for use in both non-hazardous and hazardous locations: Class 1, Division 1 and Class 1, Division 2.

Operational control and continuous monitoring by roprocessor; many built-in safety programs; self diagnostic. Pressure relief lid and cover system prevents pressure build up over 1.0 PSI.

- The UNRURS900EP2 is a stainless steel constructed, direct electric heat recycler.

- Two diaphragm pumps transfer dirty solvent in, and clean solvent out, to a Uni-ram gunwasher or drum.

- Computer controls provide precise heating cycle with automatic or timed shut-off.

- Digital LCD (16 characters) shows selected temperature set point in Fahrenheit or Celsius.

- Machine is certified for class one, division one, and class one, division two hazardous areas, and unattended use.

Features:

- Tank Size: 6.6 US Gal (25 litres)

- *Tank Capacity: Approximately 5 US Gal

- Speed: 6.6 US Gal in about 4-6 hours

- Solvent Transfer: Auto-transfer, in and out

- Air Pressure: Min 85 PSI, unit complete with pressure regulator and filter

- Power Supply: 220/240V, 2200W, 9.3A

- Heater: 2100W

- Enhanced Control Features and Digital Display — Easy settings for:

-

-

- dryer waste residue

- automatic or timed heater shut-off

- maximum temperature set points in ° or °

- regulatation of the rate of recycling using heating power percentage

-

Benefit:

No pails to lift, no solvent to pour. Shop safety improves, less back strain and less solvent spillage.

The URS900EP2 is designed to connect to and recycle used solvent from E-model spray gun and pressure pot cleaners such as UG4000E, UG6000E, UG5000EW, UG6000EH, UPP6500E and UG7500E. These units are equipped with special pails and hoses to permit easy flow of solvent to and from the solvent recycler.

The transfer system of the URS900EP2 includes:

Two dual diaphragm pumps, two 5-minute timers, a receiving pail, hoses and fittings.

URS900SS:

Is a URS900EP2 with a stainless steel condenser and fittings to resist acidic and corrosive solvents. The URS900EP2 has a copper condenser with brass fittings.

WATER: Use the URS500SS to recycle water or used solvent that includes water. Water can corrode a copper condenser but not a stainless steel condenser.

URS900EP2SS

Is the same as URS900SS except dirty solvent is pumped directly into the distillation tank and clean recycled solvent is pumped from the receiving pail to an external clean container. Pumps are activated by turning a timer.

Consumables:

- a high-temperature liner bag, supplied as a 10-pack (part number LB900C-10), is required for every recycling batch.

- Replace the lid gasket in your unit at least once every 6 months. Part numbers are shown below.

| Part Number | Material |

| 770-2190N | Neoprene |

| 770-2150V | Viton |

| 770-2150TE | Teflon |

Related Products

$6,550.00 – $9,680.00Price range: $6,550.00 through $9,680.00