- Home

- All products

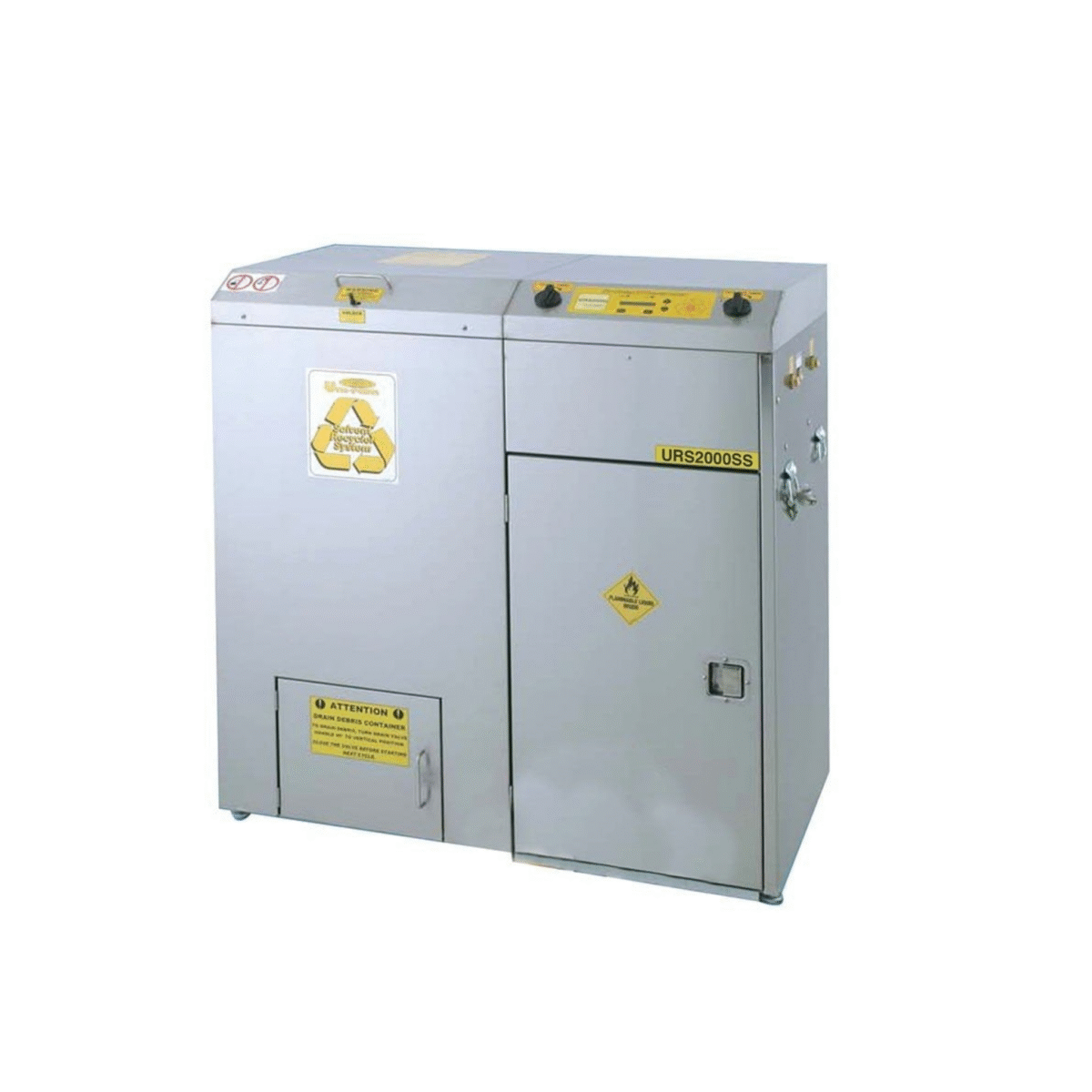

- URS2000SS Solvent Recycler

SKU:

URS2000SS Solvent Recycler

$32,630.00

The URS2000SS model offers 20 gallons (75 liters) of recycled solvent per batch, featuring similar advanced technology and safety measures. The Uniram URS2000 Series Solvent Recyclers are designed to provide clean recycled solvents daily, such as paint thinner and acetone. These recyclers help reduce a shop’s environmental footprint and save costs by lowering solvent purchases and off-site disposal expenses by approximately 90%.

Specifications

Product Description

Applications

Additional Information

Specifications

-

Capacity: 20 gallons (75 liters) per batch

-

Power Supply: 220-240V, 3400W heating element

-

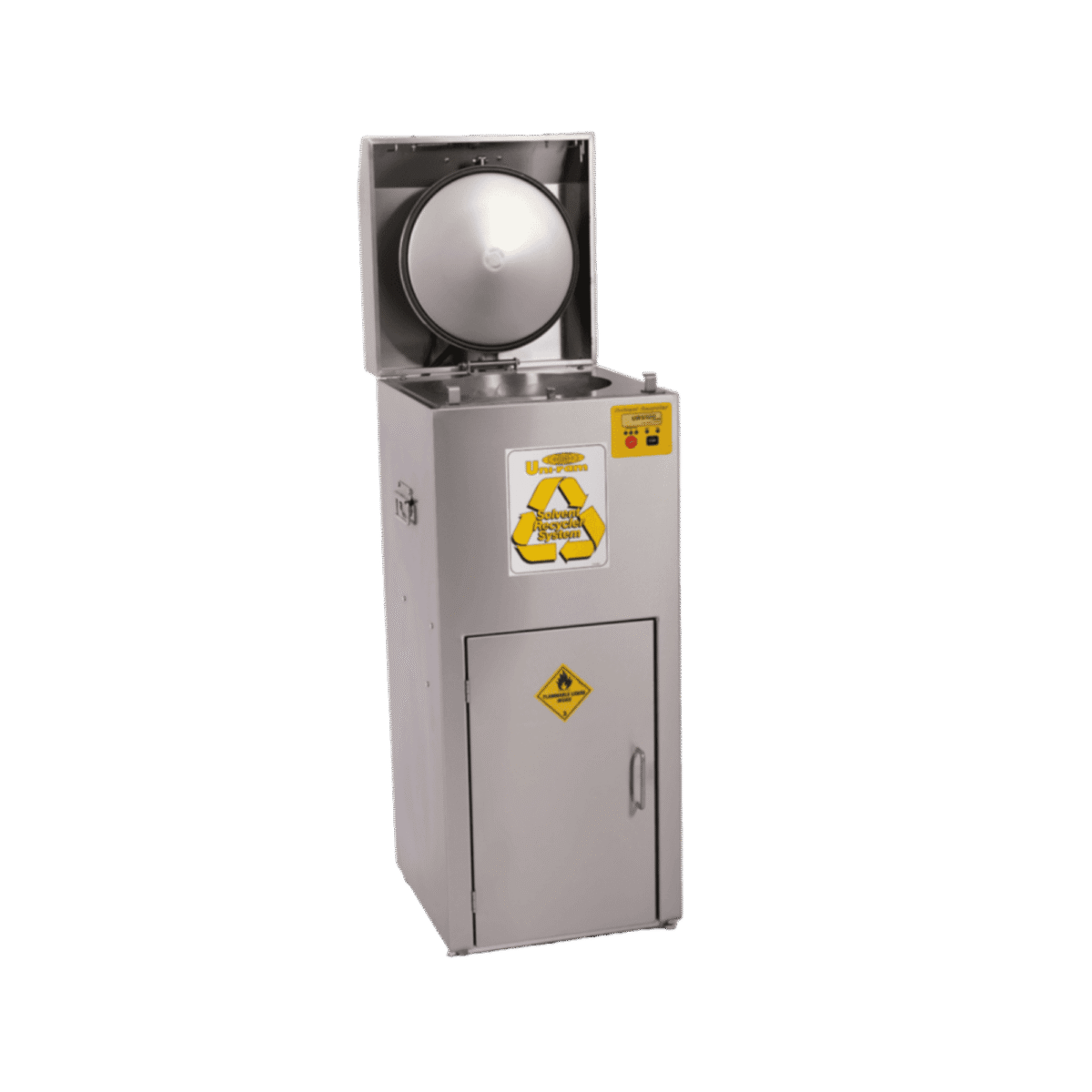

Distillation Process: Vaporization and condensation

-

Microprocessor Control: Solid-state microprocessor for managing workflow and monitoring

-

Temperature Control: Adjustable in one-degree increments

-

Self-Diagnostic System: Plain-English fault descriptions for easy troubleshooting

-

Dual Pump System: Pumps dirty solvent into the distillation tank and clean solvent into a clean drum

-

Construction: 304-grade stainless steel cabinet, cover, and lid

-

Condenser: High-efficiency, air-cooled, 316-grade stainless steel

-

Safety Certifications: UL 2208 and CSA 22.2 no. 30 and 88, lid pressure relief, optional lid lock

-

Compressed Air Supply: Minimum 85 psi, 2 cfm of clean dry air

-

Pump: 4″ dual diaphragm pump, output of 3.7 gal/min

-

Dimensions: 42″ (W) x 23″ (D) x 47″ (H)

-

Shipping Dimensions: 49″ (W) x 29″ (D) x 54″ (H)

-

Weight: 500 lbs

Product Description

The URS2000SS model offers 20 gallons (75 liters) of recycled solvent per batch, featuring similar advanced technology and safety measures. The Uniram URS2000 Series Solvent Recyclers are designed to provide clean recycled solvents daily, such as paint thinner and acetone. These recyclers help reduce a shop’s environmental footprint and save costs by lowering solvent purchases and off-site disposal expenses by approximately 90%.

Key Features:

- Capacity: 20 gallons (75 liters) per batch

- Power Supply: 220-240V, 3400W heating element

- Distillation Process: Vaporization and condensation

- Microprocessor Control: Solid-state microprocessor for managing workflow and continuous monitoring

- Temperature Control: Adjustable in one-degree increments

- Self-Diagnostic System: Monitors operations with plain-English fault descriptions

- Dual Pump System: Pumps dirty solvent into the distillation tank and clean solvent into a clean drum

- Construction: 304-grade stainless steel for the cabinet, cover, and lid

- Condenser: High-efficiency, air-cooled, made from 316-grade stainless steel

- Safety Certifications: Certified to UL safety standard 2208 and CSA standard 22.2 no. 30 and 88, with features like a lid pressure relief system and optional lid lock

Operation:

To operate, set the timer to pump 20 gallons of used solvent into the distillation tank. Press start to activate the heating element, vaporizing the solvent. The vapor then travels through the condenser, cools into liquid form, and flows into the receiving pail. Residue is collected in a heat-resistant liner bag for disposal.

Typical Applications:

- Reclaiming lacquer thinners and acetone for cleaning spray guns and other equipment

- Reclaiming acetone used in making fiberglass products

Typical Users:

- Industrial Paint Shops

- Fiberglass Fabricators

- Printers

- Metal Fabricators

Specifications:

- Compressed Air Supply: Minimum of 85 psi, 2 cfm of clean dry air

- Pump: 4″ dual diaphragm pump, output of 3.7 gal/min

- Dimensions: 42″ (W) x 23″ (D) x 47″ (H)

- Shipping Dimensions: 49″ (W) x 29″ (D) x 54″ (H)

- Weight: 500 lbs

Consumables:

- High-temperature liner bags (10-pack, part number LB2000E-10)

- Lid gaskets (replace every 6 months):

- Neoprene (part number 965-2190N)

- Viton (part number 965-2150V)

- Teflon (part number 965-2150TE)

The URS2000SS provides 20 gal of clean recycled solvent from each recycling batch.

| URS500 | URS900SS | URS1600SS | URS2000SS | |

| Capacity | 5 gal, 20L | 5 gal, 25L | 16 gal 60 L | 20 gal 75 L |

| Input | 110-120V | 220-240V | 220-240V | 220-240V |

| Heating Element | 1500 W | 2100 W | 3400 W | 3400 W |

URS2000CE Solvent Recycler

The URS2000CE model efficiently recycles 75 liters of solvent per batch, incorporating advanced features for optimal performance and safety.

| URS600CE | URS900CESS | URS1600CESS | URS2000SSCE | |

| Capacity | 19 L | 25 L | 60 L | 75 L |

| Input | 220-240 | 220-240V | 220-240V | 220-240V |

| Heating Element | 2100 W | 2100 W | 3400 W | 3400 W |

Safety and Usage Advisory

Do not recycle solvents containing nitrocellulose or peroxides due to their low auto-ignition temperature and thermal decomposition. Always check the Safety Data Sheet of both the solvent and waste material for these substances.

Applications

Applications:

The Uni-Ram URS2000SS 220-240 Volt, 20 Gallon Solvent Recycler is ideal for recycling solvents used in a variety of industries, including:

- Manufacturing

- Coating

- Automotive

- Metal Finishing

- Printing & Ink

- Electrical

- Oil & Gas

- Fiberglass

- Furniture & Cabinetrv

- Aerospace &Marine

- and more

Additional Information

Consumables:

- High-temperature liner bags (10-pack, part number LB2000E-10)

- Lid gaskets (replace every 6 months):

- Neoprene (part number 965-2190N)

- Viton (part number 965-2150V)

- Teflon (part number 965-2150TE)

| Part Number | Material |

| 965-2190N | Neoprene |

| 965-2150V | Viton |

| 965-2150TE | Teflon |

Related Products

$6,550.00 – $9,680.00Price range: $6,550.00 through $9,680.00